STEAM ENGINE

Steam engines are the most powerful source of kinetic energy in the mod.

In fact, a max-level steam engine can reach 294,912 SU.

Yes, I said levels — the power of steam engines (or boilers) is measured in levels

(as well as SU), as you can guess: the higher the level, the more SU and RPM

it produces.

|

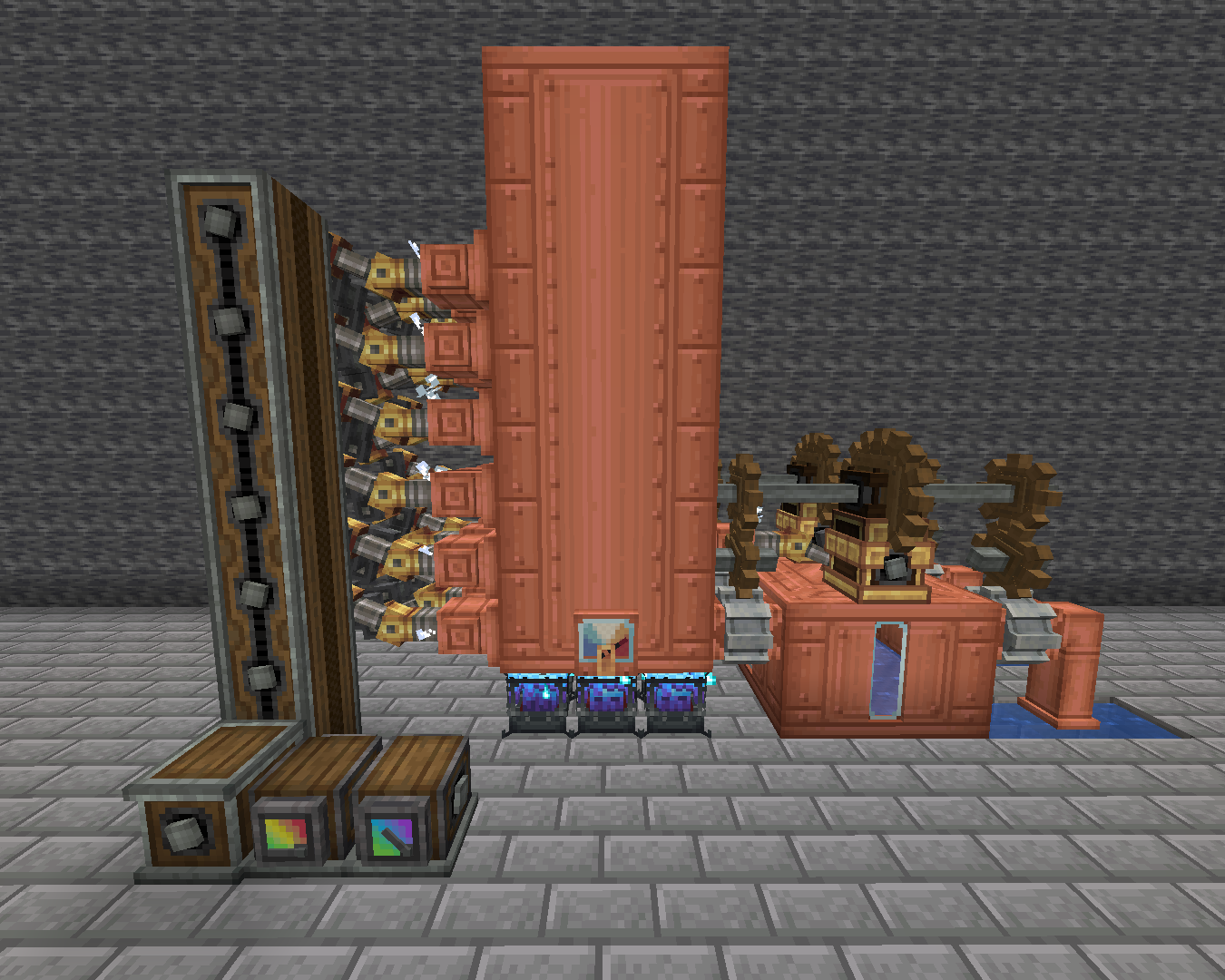

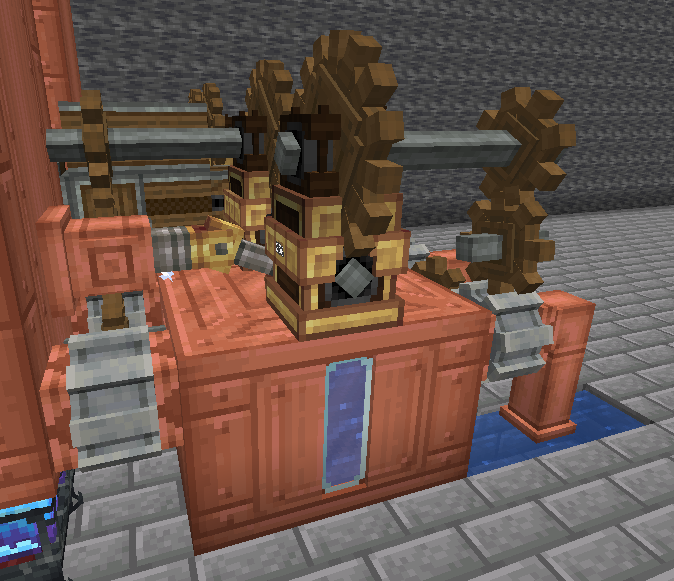

| Here’s an example of a max-level boiler |

At first glance, it may seem confusing, but in reality, it’s very easy to

understand.

Let’s break it down into sections so it’s easier both to understand and to explain:

1. OUTPUT SU AND RPM

|

| This is what it looks like |

This section is the one that will connect to the system and will provide

it with power (SU) and, in some cases, also speed (RPM).

There are several blocks, each with its own function:

- 18 steam engines

- 18 shafts

- 9 encased chain drives

- 1 horizontal transmission (gearbox)

- 1 speedometer/stressometer

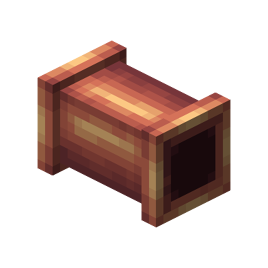

STEAM ENGINE (BLOCK)

Steam engines are the ones that produce SU; they need to be connected to

a boiler and, to transmit the kinetic power they generate, to a shaft.

For a level 18 boiler (the maximum level), at least 18 steam engines are

needed to generate all the potential kinetic energy. If you place more than

18 engines, the SU of each engine will be:

294,912 SU (the maximum a level 18 boiler can generate) divided by the number

of steam engines.

|

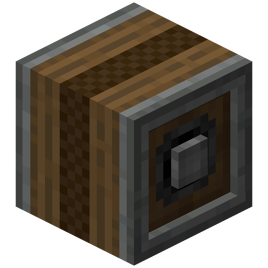

| Here’s what a steam engine looks like |

|

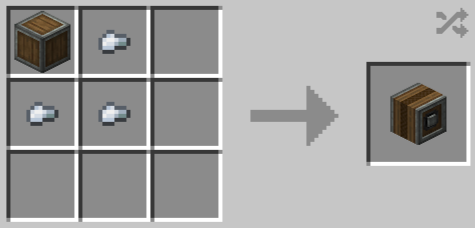

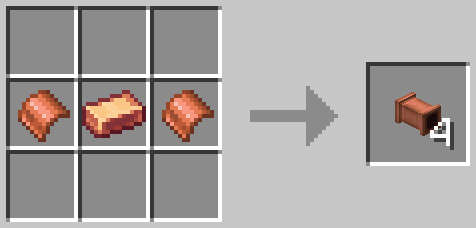

| And this is the recipe |

Each steam engine in a boiler is independent from the others. As you can

see in the image of the level 18 boiler, I placed an engine at the back

to power the pumps that feed water into the boiler. In fact, engines can

be placed anywhere around the boiler you want.

Each individual engine generates between 2,048 SU and 16,384 SU and can run

at a minimum of 16 RPM up to a maximum of 64 RPM.

SHAFTS

Shafts are used, as mentioned earlier, to transfer, in this case, the kinetic energy produced by the steam engines to the coated chain drives.

ENCASED CHAIN DRIVES

Encased chain drives are shafts that can transfer kinetic energy both horizontally and vertically.

|

| Here’s what an encased chain drive looks like |

|

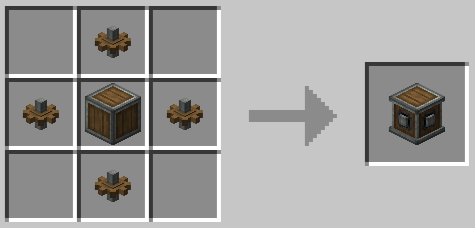

| And this is the recipe |

They are not crafted only with iron nuggets, but also with zinc nuggets. This makes them easier to craft, because if you don’t have one material, you can use the other.

HORIZONTAL / VERTICAL TRANSMISSION (GEARBOX)

Gearboxes are used to distribute the kinetic force input on one side to

three other sides, but in the opposite direction of rotation. Depending

on the type (horizontal or vertical), it distributes the rotation; in

this case, it distributes it horizontally.

It can be connected to a shaft and will not consume any SU, and the other

outputs will rotate at the same speed.

|

| Here’s what a horizontal gearbox looks like |

|

| And this is the recipe |

To craft the vertical version, simply place the horizontal gearbox in the crafting grid, and you will get the vertical gearbox.

SPEEDOMETER / STRESSOMETER

We have already talked about

both,

but in the following chapters there will be a more detailed guide

on how they work.

The tachometer will show that the system is running at 48 RPM;

While the stressometer will show that the system produces 279,390 SU, not

294,912 SU, because there is an engine at the back that takes part of the

energy the boiler can generate.

2. BOILER WITH BLAZE BURNERS

|

| This is what it looks like |

This section is where the actual boiler is located, meaning where the

water is inserted and, with the help of blaze burners (but also other heat

sources), steam is produced, which is then used by the engines.

It is made up of 2 components:

FLUID TANK

As the name suggests, these are the tanks where the input and output are

connected.

So, you can consider them the “heart” of the boiler, since this is where

the water turns into steam, which is then used by the steam engines.

|

| Here’s what a fluid tank looks like |

|

| And this is the recipe |

A boiler is made up of at least 4 tanks, with no real maximum, but it’s

useless to go beyond 72 (3x3x8), since adding more doesn’t provide any

additional benefits. So, to save materials, 72 is the recommended

maximum.

When a steam engine is placed on top, its appearance changes by adding a

“display” that shows the boiler’s level.

They’re not only used for steam engines but also for storing water (which

is pretty obvious from the name). And if they’re “linked” to a display link,

you can see the contents.

A single tank can hold up to 8 buckets (8,000 mB). They can be connected

with other tanks to form towers up to 32 blocks tall, but the base size depends

on how many tanks are placed. This way, you can store up to 2,304 buckets

of any fluid.

The minimum base area is 1 block, up to a maximum of 3x3.

Here are the different heat levels with their corresponding blocks:

-

Passive (0 heat levels):

- Fire

- Campfire

- Lava

- Magma block

- Blaze burner, but lit with flint and steel

- Extinguished blaze burner

-

Active (1 heat level per blaze burner):

- Lit blaze burner

-

Overclocked (2 heat levels per blaze burner):

- Superheated blaze burner

BLAZE BURNERS

Blaze burners are one of the heat sources for boilers and also the most

powerful, on par with the boiler heater from the New Age add-on.

To work, they require flammable materials.

|

| Here’s what an empty blaze burner looks like |

|

| And this is the recipe |

To place the blaze inside the empty “cage,” you need to right-click

either on a blaze or on a blaze spawner, so it can also be done in

Peaceful mode.

Blaze Burners have 3 stages:

|

| This is the smouldering stage |

|

| This is the heated stage |

|

| This is the superheated stage |

SMOULDERING

“Smouldering” means when the Blaze Burner is passive, so when it hasn’t

been given any fuel to consume. Even so, it can still provide a very

small amount of heat to boilers.

This stage provides a passive heat level (similar to a campfire).

HEATED

“Heated” is when the Blaze Burner has been fueled with a flammable

material (e.g. coal, wood, lava, etc.). For this stage, the best

material to use is lava because it lasts a long time and is very simple

to automate with Create.

This stage provides one heat level for the Blaze Burner.

SUPERHEATED

This is the most powerful stage of all.

To reach this level, a special item is required: the Blaze Cake.

|

| Here’s what a blaze cake base looks like |

|

| And this is the recipe |

|

| This is the blaze cake |

|

| And this is the recipe |

With this stage, all Mixer recipes are unlocked — in particular, it

enables the ability to craft Brass.

This stage provides 2 heat levels per Blaze Burner.

OTHER USES

Blaze Burners are not only used as a heat source for boilers, but also

for Bulk Smoking and Bulk Haunting. To use them in these cases, you need

to light the empty cage with Flint and Steel so that a Campfire flame

appears.

For Bulk Haunting, you need to feed it either Soul Sand or Soul Soil, which

will create a blue Campfire flame inside the cage.

3. WATER INPUT

|

| This is what it looks like |

This part is the final one — but not the least important — it’s where the

water is inserted.

However, this design is not very efficient and doesn’t perform its function

very well, so we decided to analyze another design instead, which is more efficient

and properly does what it’s supposed to do.

|

| This is what it looks like |

The difference between the first and the second design is only one — but a

very important one: the “buffer” fills up. It may seem like a small

detail, but it’s actually super useful because this design truly does what

it’s meant to do: serve as a backup.

It’s made up of several blocks, each one crucial:

- 18 water tanks

- 1 steam engine

- 3 shafts

- 2 rotation speed controllers

- 2 large cogs

- 6 cogs

- 4 mechanical pumps

- 4 copper pipes

WATER TANKS

In this case, the tanks serve as a buffer.

This part is extremely important because if, for any reason, the infinite water

sources disappear, there will still be a bit of water that keeps the boiler

running longer. In combination with the rear engine, this allows the boiler

to never shut off—except when, for any reason, there are no more infinite water

sources, in which case the operation will only be temporary.

STEAM ENGINE

This is the most important engine you can put in a boiler.

As mentioned before, each engine is individual, so even if the output system

goes into overstress, the engine behind still provides power to the pumps,

keeping the boiler running and thus avoiding waste of combustible materials

for the blaze burners.

SHAFT

In this case, the shafts are used to connect the steam engine to the two rotation speed controllers, and to connect the two large gears to the smaller gears.

ROTATION SPEED CONTROLLER

These blocks are used, as the name suggests, to regulate the RPM, meaning they can both decrease and increase it.

|

| Here’s what a rotation speed controller looks like |

|

| They are crafted using a brass casing and a precision mechanism |

|

| Here’s what a precision mechanism looks like |

|

| They are crafted using a gold sheet, 5 cogwheels, 5 big cogwheels and 5 iron nuggets |

These blocks are used to regulate not only the rotation speed (from 1 RPM

up to 256 RPM) but also the direction (clockwise and counterclockwise).

However, there is a cost: the inputs and outputs (since there’s more than

one) are in separate blocks. For example, the output (the large gear) in

this case is located in the block above.

Rotation speed controllers are placed next to the shafts, and since they also

function as shafts, they can replace one.

|

| As in this case |

Using two rotation speed controllers is crucial because it allows the pump

pairs to run at two different speeds.

In fact, the input pair of the buffer runs at 256 RPM, while the input pair

of the boiler runs at 180 RPM (the minimum required for a level 18 boiler),

allowing the buffers to fill up.

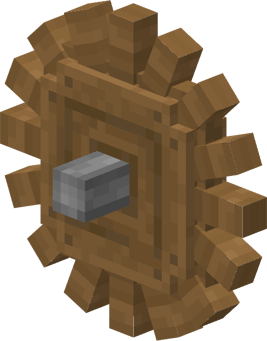

LARGE GEARS

The large gears are used to operate the rotation speed controllers,

providing either an input or an output—in this case, an output.

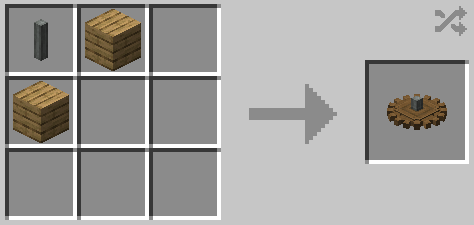

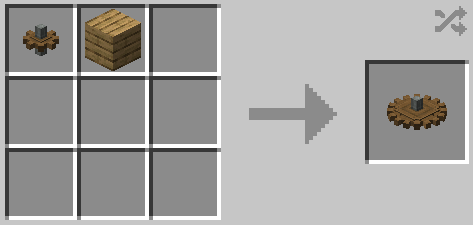

It has 2 recipes

|

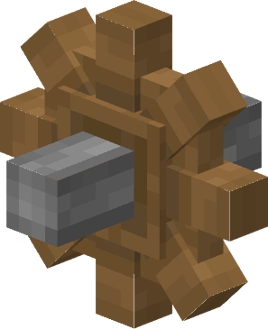

| Here’s what a large cog looks like |

|

| This is the first one, it uses one shaft and 2 wooden planks |

|

| This is the first one, it uses 1 cogwheel and 1 wooden plank |

COGWHEELS

Cogwheels are mainly used, as in this case, to transfer kinetic energy to the pumps.

|

| Here's what a cogwheel looks like |

|

| They are crafted using 1 shaft and 1 wooden plank |

Cogwheels, like the encased chain drives, can also transfer kinetic energy vertically, but every time a new gear is placed, the rotation direction changes.

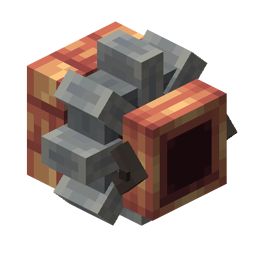

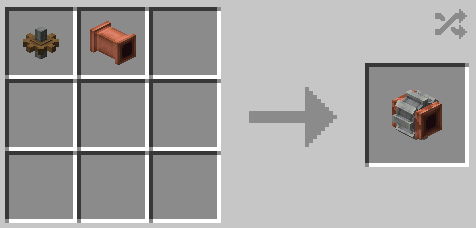

MECHANICAL PUMPS

Mechanical pumps are used to transport liquids through pipes that then end

up in tanks.

To work properly, and to draw water, they need an infinite source.

|

| Here’s what a mechanical pump looks like |

|

| They are crafted using 1 cogwheel and 1 copper pipe |

The rotation direction does not affect the flow direction, but it can be

changed with a wrench.

It can transport fluids up to 16 blocks away (configurable in the Create settings).

Here we introduce a new feature: the impact on stress.

Basically, it’s how many SU it consumes. The impact per pump is: RPM × 4.

So:

- For those running at 256 RPM: 256 × 4 = 1,024 SU

- For those running at 180 RPM: 180 × 4 = 720 SU

Thus, the buffer’s input pair has an impact of: 1,024 × 2 = 2,048 SU

While the boiler’s input pair will have: 720 × 2 = 1,440 SU

COPPER PIPES

The name is fairly self-explanatory, so it doesn’t need an introduction.

|

| Here’s what a copper pipe looks like |

|

| They are crafted using 2 copper sheet and 1 copper ingot |

They can also be crafted by placing copper plates vertically instead of

horizontally.

In this case, their use is to connect infinite water sources to the pumps.

CONCLUSIONS

With this, you know the components of a boiler and how they work. Try different layouts, play with rotation speeds and gear setups, and see how far you can push your system efficiently!